Course Search Results

Course Search Results

Course Name

Mechanical Interlocking FLMFCourse Description

Describe the engineering specifications associated with the type lever frame, lock or circuit controller for which competence is being assessed. Describe how the maintenance adjustment, faulting, repair and testing activity may affect the safe operation of the railway. Understand what terminology and methods are used to identify locking components and describe the position of a lever. Understand the reporting lines and escalation procedures.Audience

This course is designed to develop the delegates understanding of corrective and preventative maintenance techniques that need to be applied to mechanical interlocking systems. Pre-Requisites: Before attending this training a person should have successfully completed Signal Maintenance 2, SMT Core and has at least 3 years workplace experience.Duration:

10 Day(s)Class size:

4

Course Name

Mechanical Interlocking FLMFCourse Description

<p>Describe the engineering specifications associated with the type lever frame, lock or circuit controller for which competence is being assessed. Describe how the maintenance adjustment, faulting, repair and testing activity may affect the safe operation of the railway. Understand what terminology and methods are used to identify locking components and describe the position of a lever. Understand the reporting lines and escalation procedures.</p>Audience

This course is designed to develop the delegates understanding of corrective and preventative maintenance techniques that need to be applied to mechanical interlocking systems. Pre-Requisites: Before attending this training a person should have successfully completed Signal Maintenance 2, SMT Core and has at least 3 years workplace experience.Duration:

10 Day(s)Class size:

4Competence Name Awarded:

Undertake corrective and preventative maintenance of Lever Frames and Locks & Circuit Controllers.Competence Awarded:

Sig 16Course Code:

STF 107Prerequisite Name:

Undertake corrective and preventative maintenance of Track Circuits. Undertake corrective and preventative maintenance of Electrical Signals including AWS and TPWS. Undertake corrective and preventative maintenance of Signalling Power Supplies. Undertake corrective and preventative maintenance of Signalling Cables. Undertake initial diagnosis of failures to determine the necessary course of action. Undertake initial diagnosis of failures to determine the necessary course of action.Fault Finding Ensure effective progression of work and use of resources during signalling testing, maintenance or installation activities. Take and relinquish responsibility for Signalling equipment. Signal Maintenance Testing. Signal Maintenance Testing.Core Skills.Prerequisite Short Code:

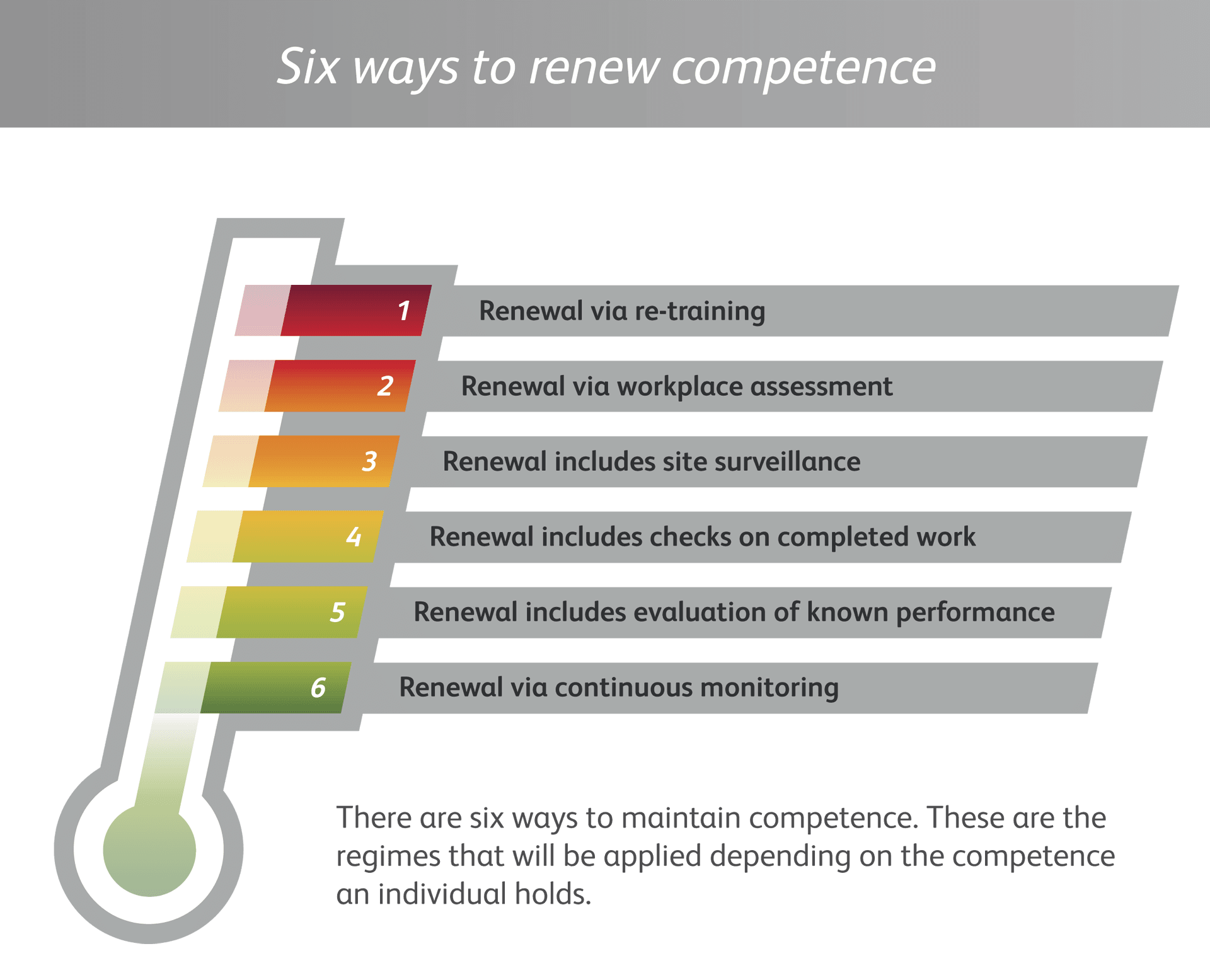

Sig 05; Sig 07; Sig 13; Sig 14; Sig 23; Sig 23.01; Sig 24; Sig 25; SMTH; SMTH.01Skills Assessment Scheme Regime:

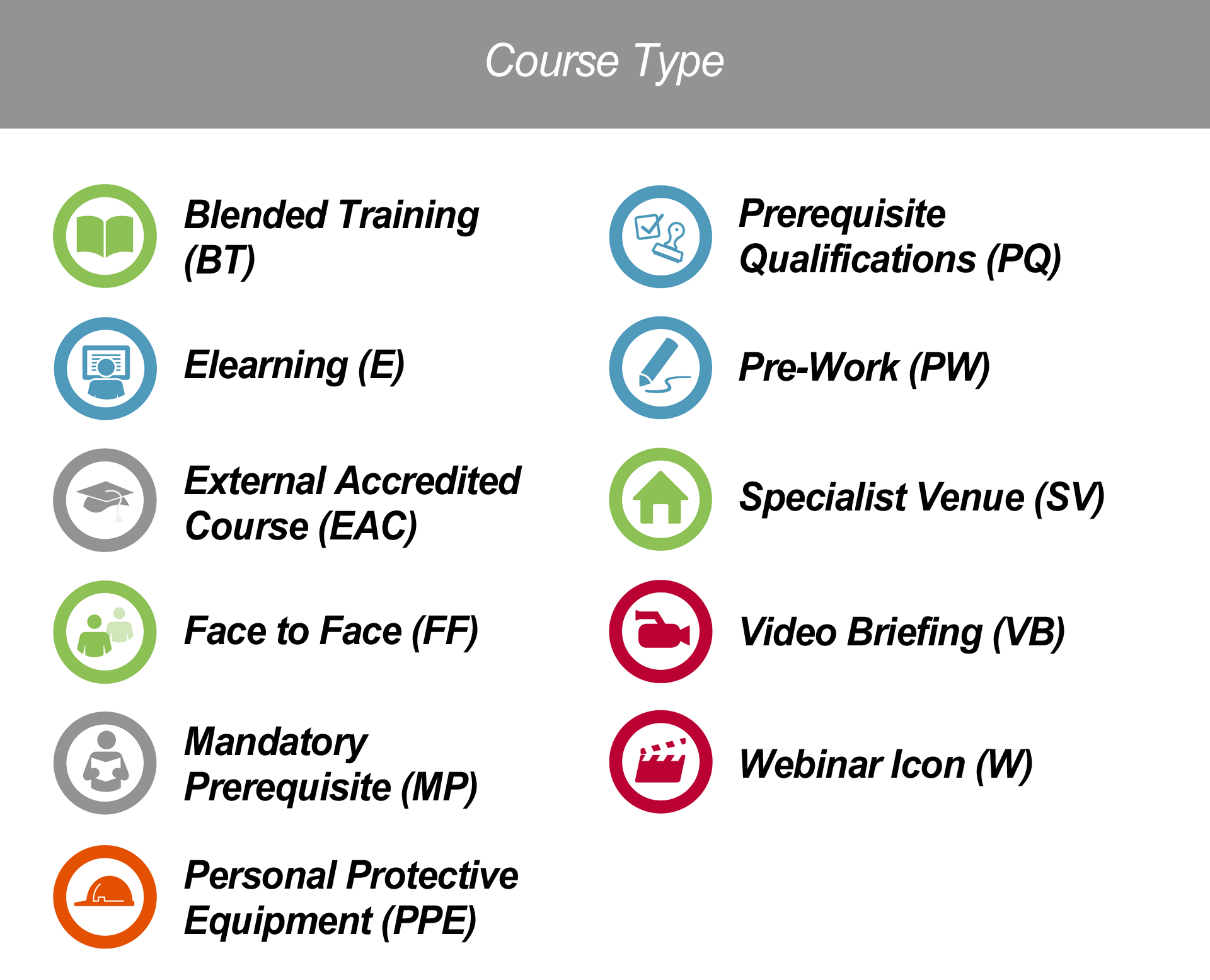

4Course Type:

Course Name

Mechanical Interlocking FLMFCourse Description

<p>Describe the engineering specifications associated with the type lever frame, lock or circuit controller for which competence is being assessed. Describe how the maintenance adjustment, faulting, repair and testing activity may affect the safe operation of the railway. Understand what terminology and methods are used to identify locking components and describe the position of a lever. Understand the reporting lines and escalation procedures.</p>Audience

This course is designed to develop the delegates understanding of corrective and preventative maintenance techniques that need to be applied to mechanical interlocking systems. Pre-Requisites: Before attending this training a person should have successfully completed Signal Maintenance 2, SMT Core and has at least 3 years workplace experience.Duration:

10 Day(s)Class size:

4Competence Name Awarded:

Undertake corrective and preventative maintenance of Lever Frames and Locks & Circuit Controllers.Competence Awarded:

Sig 16Course Code:

STF 107Prerequisite Name:

Undertake corrective and preventative maintenance of Track Circuits. Undertake corrective and preventative maintenance of Electrical Signals including AWS and TPWS. Undertake corrective and preventative maintenance of Signalling Power Supplies. Undertake corrective and preventative maintenance of Signalling Cables. Undertake initial diagnosis of failures to determine the necessary course of action. Undertake initial diagnosis of failures to determine the necessary course of action.Fault Finding Ensure effective progression of work and use of resources during signalling testing, maintenance or installation activities. Take and relinquish responsibility for Signalling equipment. Signal Maintenance Testing. Signal Maintenance Testing.Core Skills.Prerequisite Short Code:

Sig 05; Sig 07; Sig 13; Sig 14; Sig 23; Sig 23.01; Sig 24; Sig 25; SMTH; SMTH.01Skills Assessment Scheme Regime:

4Course Type:

How to Book